Maintenance of Vector and Accessories

Update Vector Firmware

Periodically, updates for Vector will be made available. Contact your supplier for more information.

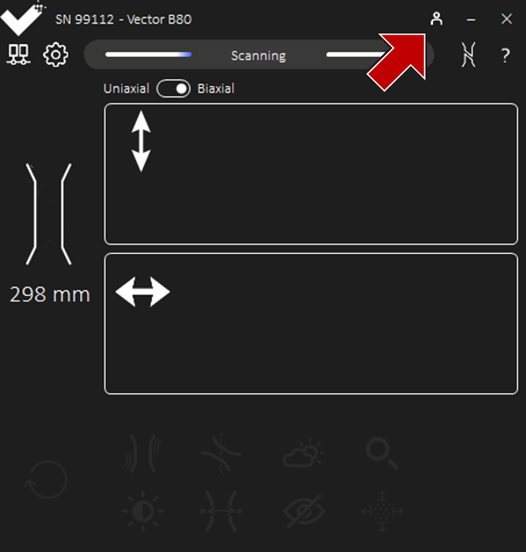

Once connected to Vector, the Help page will display the current firmware version.

Ensure the update file (.swu) is available on the connected PC via download or a USB drive.

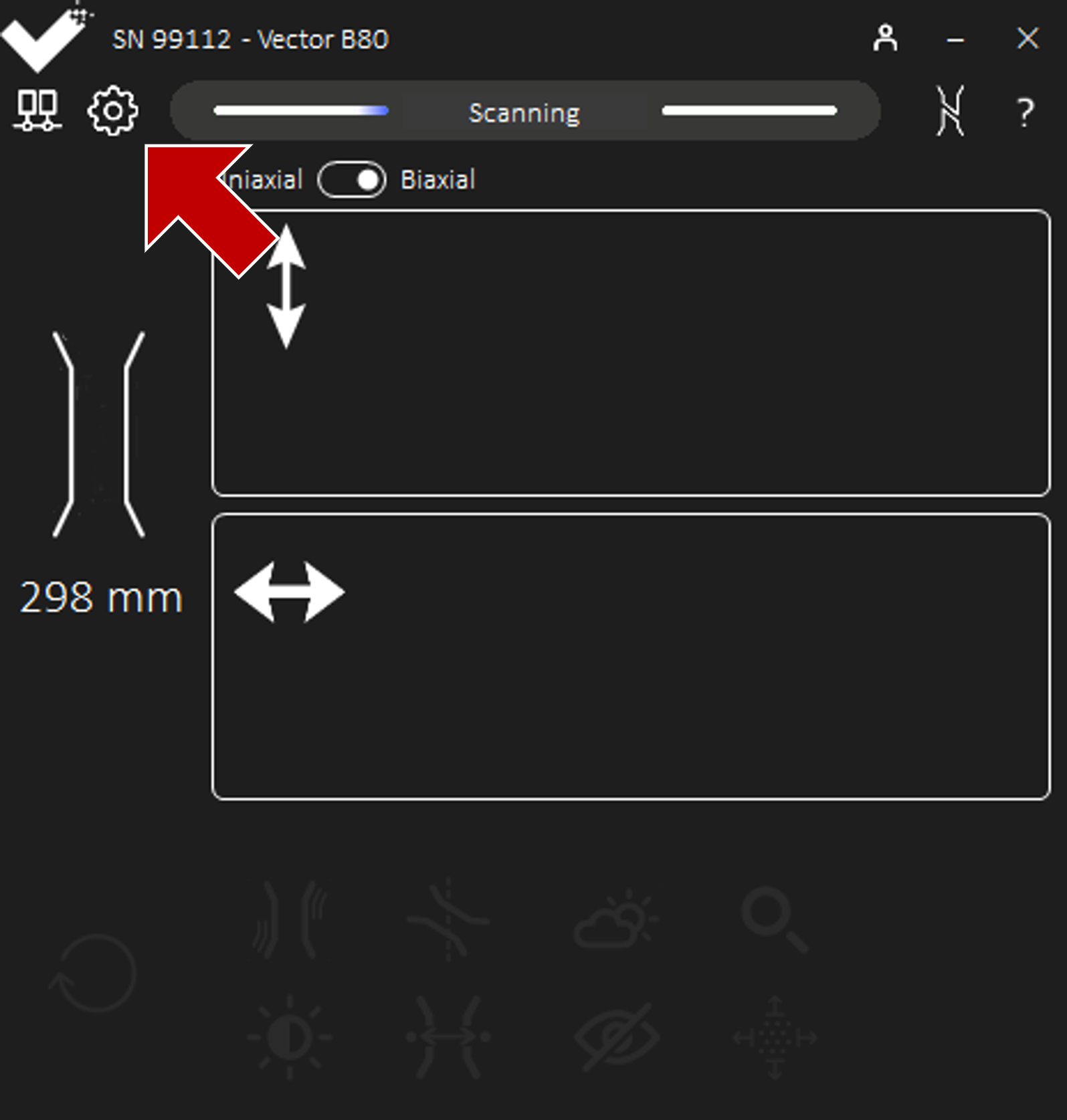

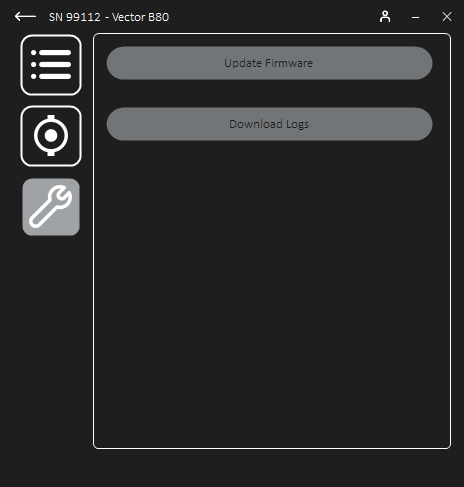

Once connected to Vector, navigate to Settings and then Service to start a firmware update.

Click on Service select the Update Firmware button. Select the .swu file and click upload.

Vector will restart when the process is complete, and a dialog box will appear to indicate success.

Warning

Do not turn off Vector or remove the power during a firmware update.

Update Vector Interface Software

Periodically, updates for Vector Interface will be made available. Contact your supplier for more information.

Ensure the update files are unzipped and available on the connected PC via download or a USB drive.

To update the Vector Interface software, launch the install wizard by running the Vector.bat file and following the steps.

Alter Vector Interface Appearance and Behaviour

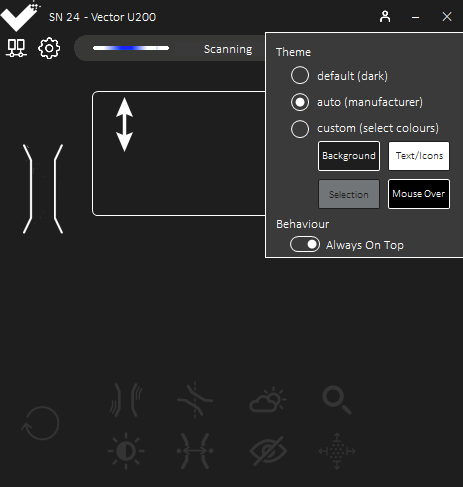

The appearance and behaviour of the Interface App can be changed using the Display Preferences.

The Theme will automatically folow the colour scheme set by the manufacturer of the connected Vector. Otherwise, choose a custom or preset alternative.

The Behaviour controls how the App displays over other programs. For accessibility and convenience, this is set to display always on top by default.

Maintenance of Vector Extensometer

Keep the front face free from dust, grease, or other contaminants.

Using care and a clean, microfiber cloth, wipe the center window.

Warning

Do not use any liquid. Do not apply pressure to the window.

Maintenance of Vector Marking Kit

For more pens, inks, stamps, or stencils, please contact your supplier.

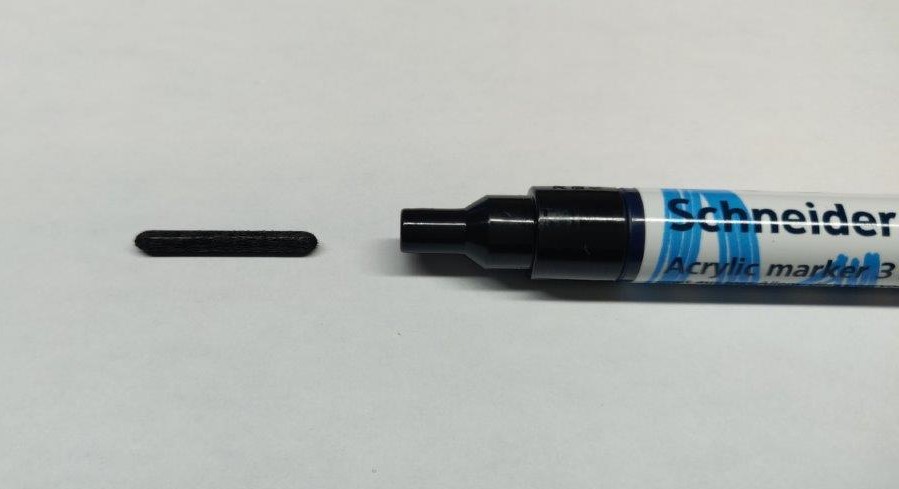

Pens and Stencils

New pens must be charged with ink to draw.

Press the nib repeatably onto some suitable blotting paper.

Note the ink wicking through the nib.

For U200

For U70 and B80

Dirty nibs can be flushed through with ink using the same charging process to clean them.

For U70 & B80, nibs are ceramic and durable. They can be easily wiped clean.

For U200, worn nibs can be removed and reversed for extended use.

Stencils must be cleaned between ink colour changes to prevent contamination of the pen nib.

Alcohol-based cleaners are common and suitable for pens, inks, stamps, stencils, and most specimens.

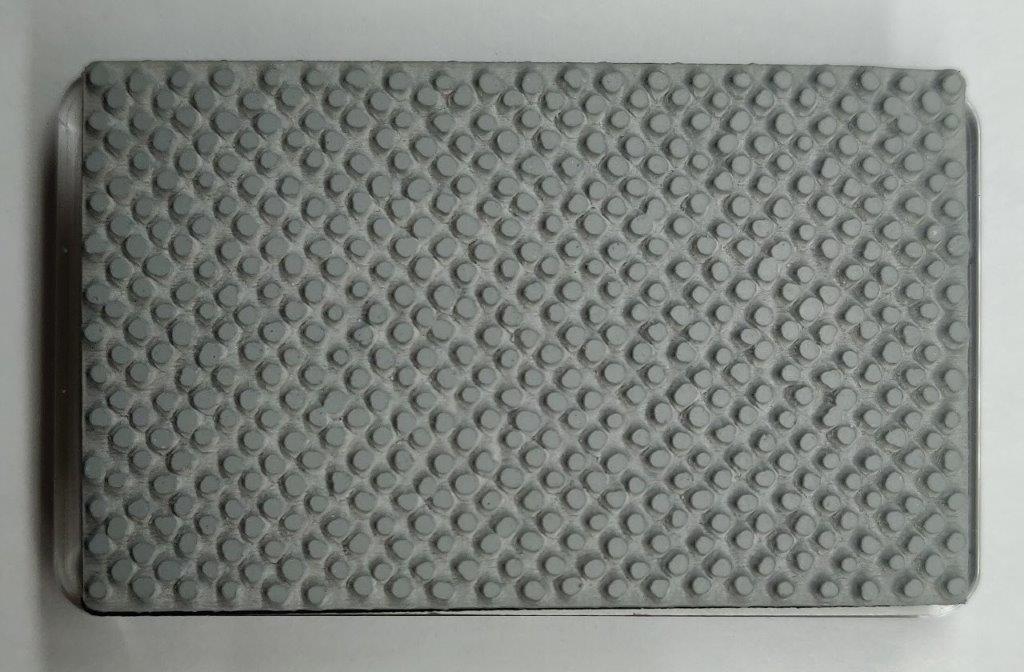

Stamps and Inks

New stamps should be primed by stamping serveral times onto a clean and grease-free scrap material.

Where possible, dedicate a stamp to a single ink tone. If changing colours, ensure the stamp is thoroughly cleaned.

Store ink pads with the lid on when not in use.

Clean stamps of any ink build up. It is recommended to perform consistent cleaning as part of standard procedures.

For reference, clean stamps are shown below.

For U200

For U70 and B80