Introduction

Manual Overview

Variants of Vector

Vector |

Operating Distance |

Axial Gauge Lengths |

Transverse Gauge Lengths |

Minimum Specimen Width |

U200 |

250 - 350 mm |

25 - 180 mm |

None |

W≥ 5 mm, or Ø≥ 6 mm |

U70 |

280 - 320 mm |

10 - 50 mm |

None |

W≥ 2 mm, or Ø≥ 2.5 mm |

B80 |

285 - 315 mm |

7.5 - 70 mm |

6.0* - 25 mm |

W≥ 1.5 mm, or Ø≥ 2 mm when axial

W≥ 10 mm, or Ø≥ 12.5 mm when transverse

|

Quick Start Guidance

English |

|

Chinese |

Specimen Marking Guidance

English |

|||

Chinese |

Contents and Parts list

Vector Extensometer

- Vector Mounting Kit

Extensometer intermediary mount

UTM Rail

Stub axle

Fastenings and tools

Ethernet Cable

Combined Power and Data Cable

Power transformer with regional mains adaptor (UK, EU, US, CN)

- Vector Marking Kit

Pens and Stencils

Inks and Stamps

- Vector Accessories

Validation Block

Production Certificate

Vector Quick Start Guide

Vector Specimen Marking Guide

USB Drive with Vector Interface Installer

Health and Safety

We recommend you always keep this manual on hand and in good condition. Users MUST familiarise themselves with the health and safety guidelines below prior to attempting to install or commission Vector.

Hold unit securely and under control when repositioning, ensuring it doesn’t come into contact with external hardware e.g. the test frame or grips.

Avoid trapping or pinching fingers in sliding or locking areas when handling Vector or its mountings.

Check the full range of motion of Vector and its mountings to prevent potential clashes and damage.

Check Vector is mounted so that access to emergency stop buttons and limit switches on the test frame are not obstructed and normal operation of the machine is not hindered.

Route cables appropriately to ensure there is no trip hazard or risk of catching onto mechanical elements of the machine.

Cables should have sufficient slack to drop freely from Extensometer to the Mounting Stub, and onto all other connections.

The optional extension arm contains an N42 neodymium magnet. Please limit proximity to medical devices e.g. pace makers, to no less than 50mm.

Risk of electrical shock - Unit should be kept away from sources of moisture at all times.

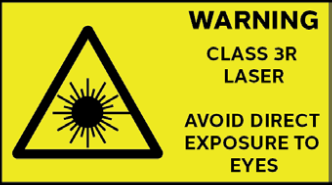

Both the person responsible for the product and any person using the equipment are required to anticipate and avoid potential hazards during operation. As per IEC TR 60825-14:2022, products containing laser class 1, class 2, and class 3R do not require a laser safety officer, protective clothing or eye-wear, or special warning signs within the working area, when operated in line with the user manual. Before using Vector, the person responsible for the product should ensure that a suitable evaluation is completed for all future users of the system, considering the current installation of Vector and the universal test frame (UTM) with regards to the laser alignment system. The following safety notes should be considered.

Only trained persons should be assigned to operate the equipment.

Take precautions to ensure that persons do not look directly into the beam.

The beam path to be located above/below eye levels wherever practicable.

Install the equipment in such a way as to prevent the beam from being unintentionally directed at mirror-like surfaces.

At the most extreme, the lasers in Vector are classified as Class 3R up to a distance of 20mm from the front face of the Vector unit. Beyond this point, they are classified as Class 2 and are considered safe due to the human blink reflex providing protection. It is important to note that local/national regulations may have more stringent requirements for the safe use of lasers than those outlined in IEC 60825-1:2014 and IEC TR 60825-14:2022.

Operating Environment

10-40°C (50-100°F), for use and storage

20-80% relative humidity non-condensing environment

Calibrated and validated at 18-22˚C - optimal measurement performance achieved at this temperature.

Battery Information

Vector contains a 50mAh Lithium cell battery. 1. Do not attempt to replace the battery yourself, opening the unit will void the warranty and may damage the battery or on-board components, which could cause overheating, fire, and injury. 2. The lithium battery in your device should only be replaced when under the service of Imetrum or an authorised service provider. 3. Under WEEE regulations the battery must be recycled or disposed of separately from household waste and in line with local laws and guidelines.