The Modulus Value was Different than Expected

Connect the Vector to the Vector Interface app to inspect the cause.

Solutions

Check the scale of the Vector analogue output matches the signal input of the test frame.

Ensure the range encompasses the expected minimum and maximum strain for the intended material and test.See section Scaling the Analogue Output Signal for more information on setting the analogue output to nominal values.Check the measurement type is as intended.

Vector outputs in either strain, as a %, or extension, in mm or inches. | See section on Setting the Measurement Type to Output for more information.Check the unit type is as intended.

Vector can be configured for mm or inches. | See section on Setting the Unit Type for Measurement and Configuration for more information.Check that markings are applied to a region that is parallel and even.

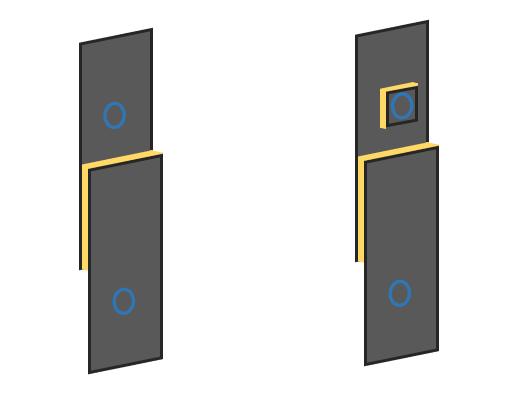

Markings that are different distances from Vector will under-report strain or extension.Markings must be applied to regions that are co-linear to eachother and parallel to the line of load.Clean the specimen and reapply, if possible. Otherwise pack the surface of the specimen to bring markings in-line.