The Modulus Curve was Not Linear or Smooth

Solutions

Check the markings have been applied correctly.

Poor markings can introduce noise, especially if the specimen has not been correctly prepared. Ensure the specimen is free from grease or dust before marking.See section on Specimen Marking for more information.Check markings are suitable.

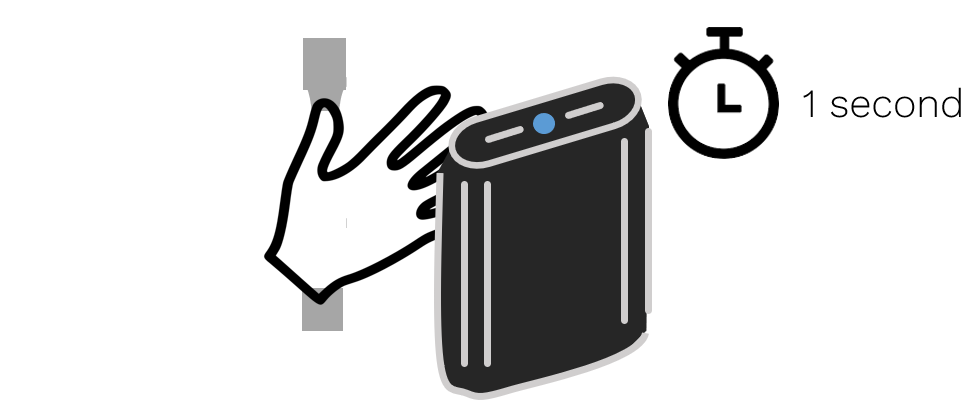

When measuring transverse strain, rings are recommended on flat specimens.See section on Specimen Marking for more information.Reset Vector with a “handstop” before the start of each test.

Ensure the specimen or grips are not slipping.

Clean the jaw faces, lubricate the jaws, and use correct clamping pressure to hold the specimen.Apply more preload to the specimen then reset Vector with a “handstop”.

A slack or twisted load-train is likely to move as further load is applied. This can result in artifical strain values at the start of the test.Set the load-train straight and rigid, or apply more preload.Ensure no Vector Interface is searching Vector on the network during the test.

Interuptions from the network can result in noise or variations in the output signal. When testing, ensure the Vector Interface is connected to the intended Vector.See section Connecting to Vector for more information.