Specimen Moved

Specimen Moved

The position of the markings has changed relative to Vector since they were detected.

Solutions

Check that Vector is not moving and all mounting locking levers are secure and locked off

The Vector can slide down if the UTM rail lever is not secure. Similarly, if other levers are not locked off, the Vector is free to move and would be affected by vibrations.

Check that the test frame is not moving, and there is sufficient rigidity in the load train to hold the specimen stationary.

Tightening the load train elements prior to mounting a specimen to limit the motion of the specimen as force is applied during the start of a test.

Apply more preload to the specimen then reset Vector with a “handstop”.

Information

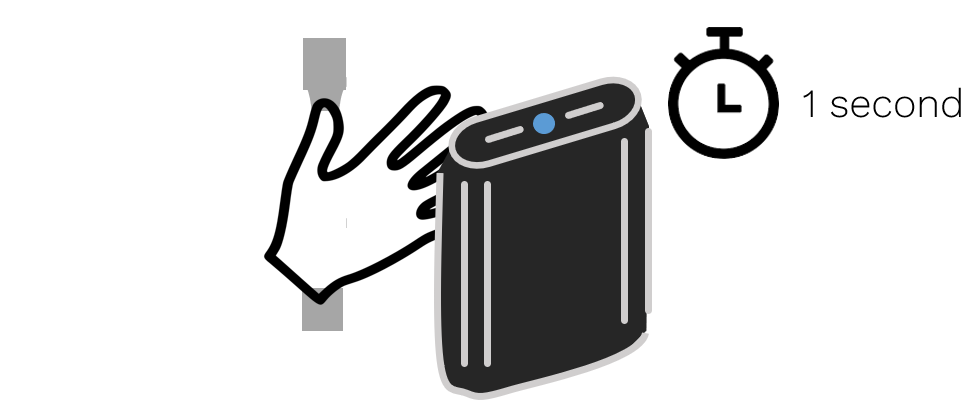

After moving the module or specimen, wait a few seconds for warning indicators to settle.

Warning

Rigid and misaligned load trains can introduce bending moments to the specimen, resulting in error.