No Markings Detected

No Markings Detected

Vector is unable to detect markings due to a number of possible reasons. Markings may not be to specification, or not visible to Vector. Surrounding features may be obstructing or distracting.

Solutions

Check that markings have been applied correctly to the specimen.

Vector can detect and measure ring, dots, and speckle markings. See Specimen Marking for more information.

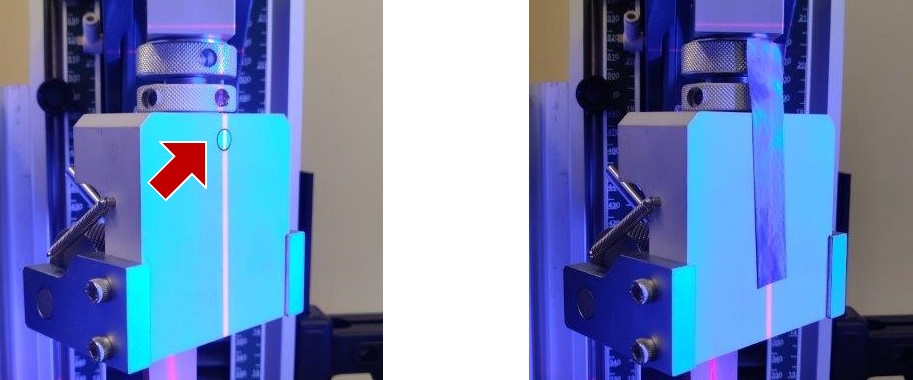

Check laser guides are aligned with specimen markings.

Vector measures markings within a calibrated region. See Vector Lasers Not Aligned to Specimen for more information.

Check Vector is positioned at a suitable Operating Distance from the specimen markings.

Vector measures markings within a calibrated region. See Vector Outside of Operating Distance for more information.

Check that there are no obstructions preventing measurement.

Markings can be obscured from the Line of sight of Vector. Obstruction.

Check for circular or textured objects on the grips or fixtures visible to Vector.

Obscure any round holes, locking pins, bolt heads, or highly textured components which can be mistaken for rings, dots, or speckle regions. Where possible and convenient, rotate components that contain these features, or use tape to mask.

Check the center window of vector is clean and clear.

Using care and a clean, microfiber cloth, wipe the center window free of dust, grease, or other contaminants. Do not use any liquid. Do not apply pressure to the window.

For round specimens, check that the marked side of the specimen is fully facing Vector

Check that the full width of the specimen is marked and presented towards Vector. In many cases, a round specimen can be easily rotated to show a full region of speckle markings.

For speckle markings, check the region has sufficient ratio between width and height.

Vector requires speckle regions to have a length atleast 1.4x width.

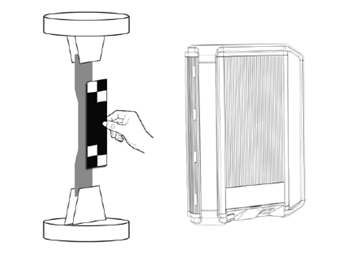

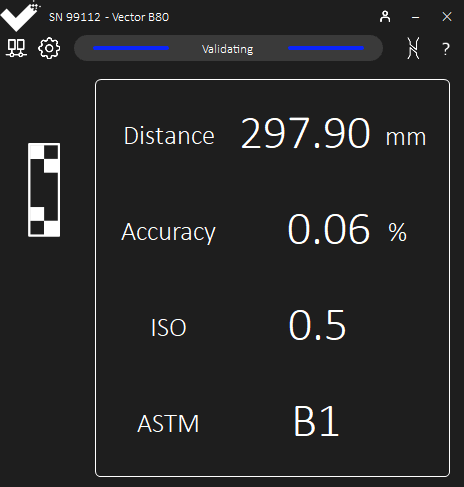

Use the Validation Block against the specimen to confirm it is detected by Vector.

The “Validation Block” is a simple bar used to quickly gauge the measurement performance of Vector. It can be used to display a live read-out in the Interface App. See Validation Block Information via the Vector Interface in the User Guide for more information.If Vector does not detect the Validation Block, and there are no obstructions to the line of sight, then the Vector may have developed a fault. In this case, contact the supplier for assistance.

Information

After moving the module or specimen, wait a few seconds for warning indicators to settle.